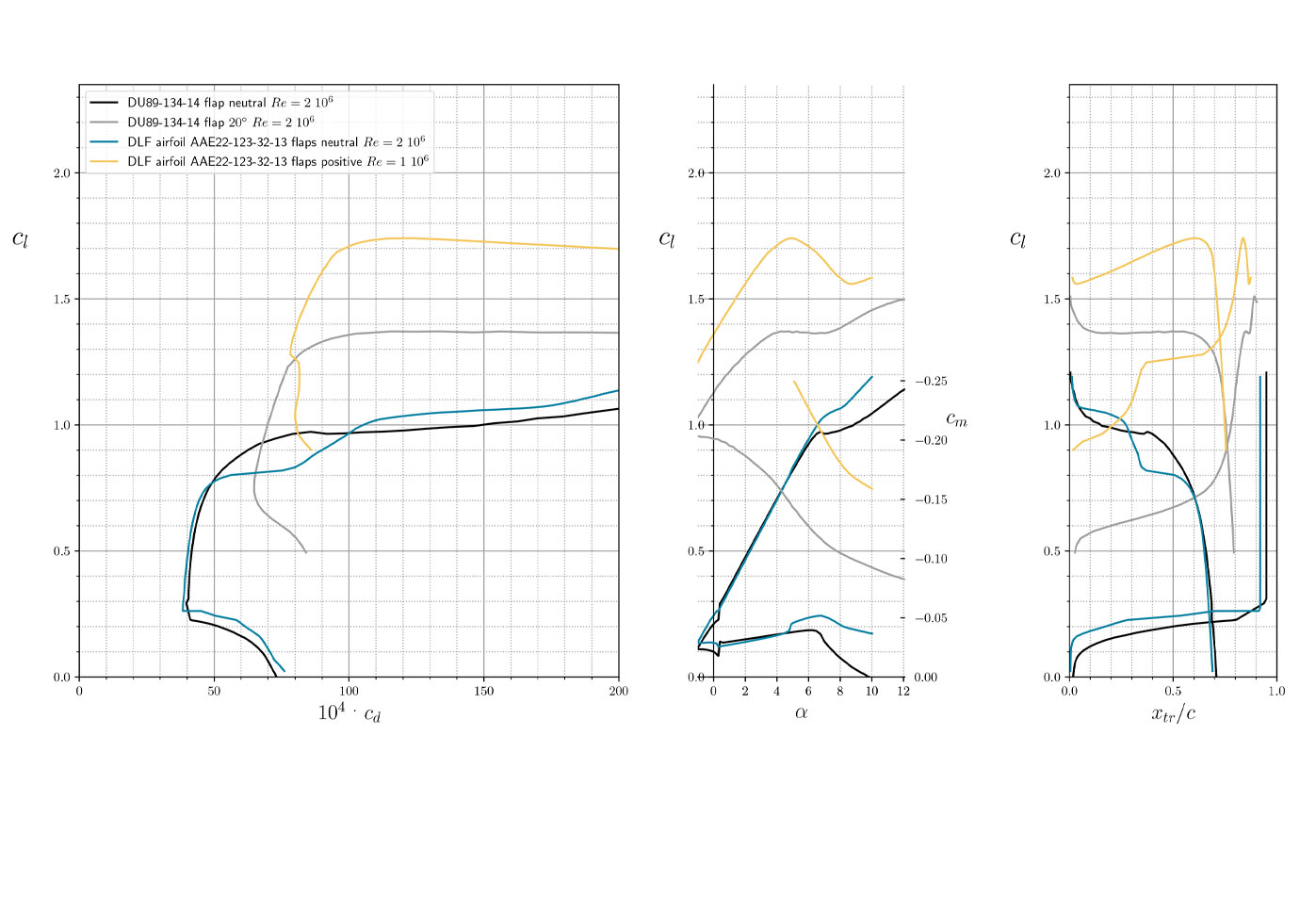

Our airfoil technology (patent pending) increases the useable range of lift coefficients with low-drag laminar flow significantly compared to airfoils with a camber changing flap.

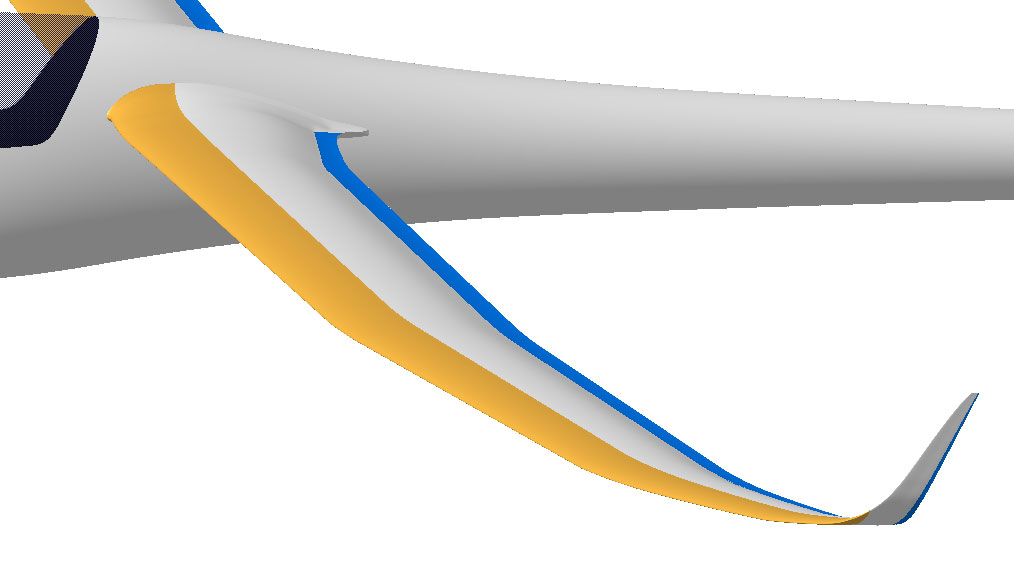

The new airfoil technology comprises of a leading edge flap in combination with a trailing edge flap. It has a sophisticated geometry. If the leading edge flap is in the high lift position, the top side of the profile, which is sensitive to the flow, is kink-free and continuous. In the low lift position the bottom side is flow-critical and then forms a kink-free and steady surface. In combination with a proper sealing technique, this property makes it possible to keep the flow on the profile laminar. The wider usable range of lift coefficients makes it possible to reduce the wing area and reduce profile drag while maintaining the same maximum lift. If you are interested in the technology feel free to contact us.